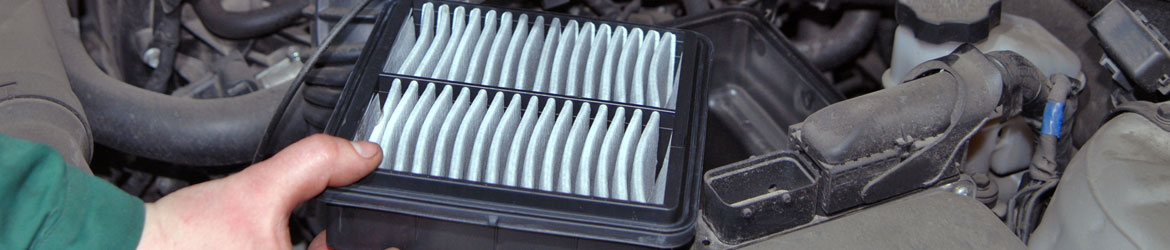

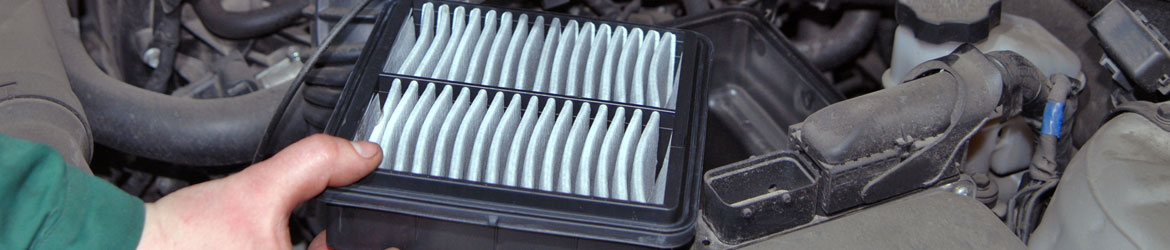

| Occasionally OEM components have flaws in design. Each component is analysed and measured to verify OEM tolerances, this allows us to resolve design conflicts. Our environmentally controlled assembly and test room ensures a trouble free assembled compressor. The final assembly process is the culmination of teamwork, training and the continued implementation of various lean manufacturing techniques. Our strict control methods allow us to produce consistent results time after time. Our commitment to OE quality assures our customers that we are working to ISO 9002 & TS16949 QC standards. At Compressortech, Quality Assurance is not just an empty phrase.

|

|

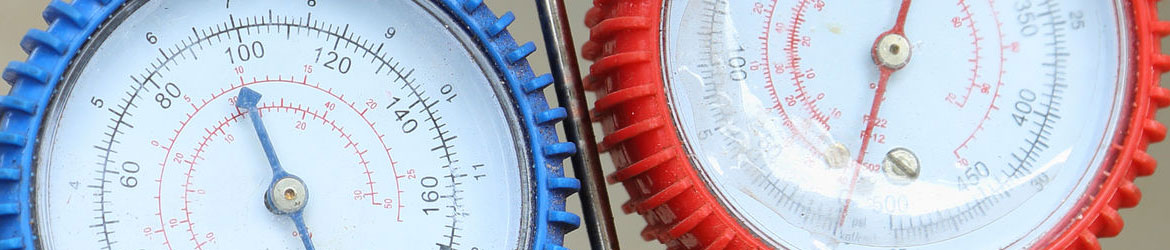

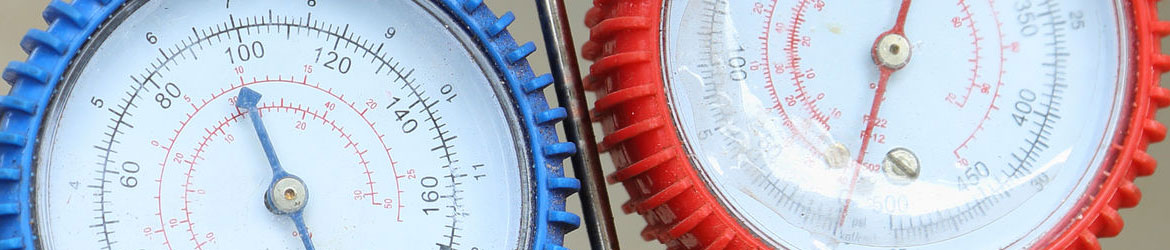

Modern quality systems rely on trace-ability and accountability throughout the entire process. Each Compressortech remanufactured compressor is 100% NLP. (noise, leak, performance) tested. Our computer based test bench converts the raw output data, comparing this information against OEM parameter specifications – like an engineers note-pad. All information regarding the entire remanufacturing and testing procedure for each type of compressor is recorded and stored which allows us to provide 'total traceability and accountability'. Regular audits are carried out on our entire remanufacturing process. |